Percentage Of Manganese In Stainless Steel

Manganese is a key component of low cost stainless steel.

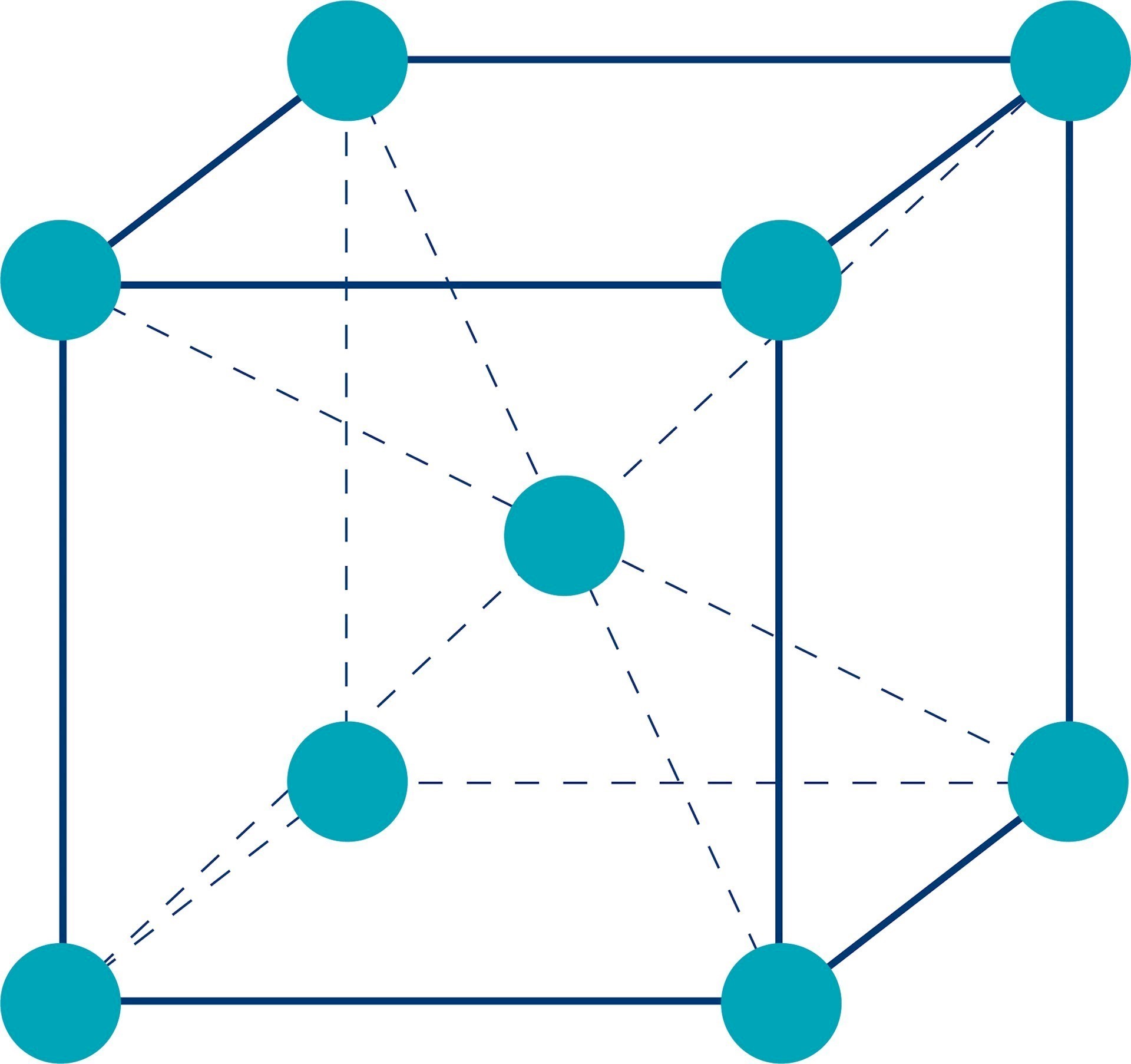

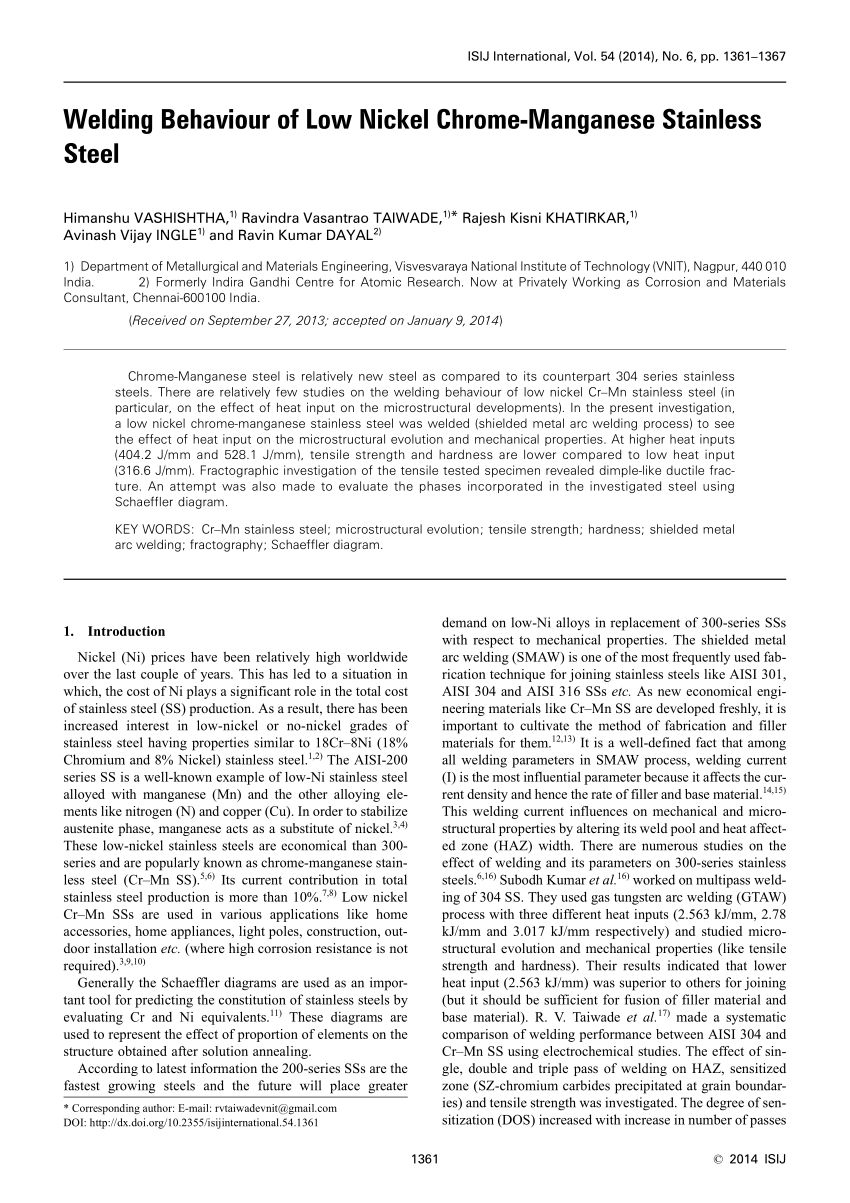

Percentage of manganese in stainless steel. It depends on the specific alloy. Manganese like nickel is an austenite forming element and has been used as a substitute for nickel in the aisi200 series of austenitic stainless steels e g. Pure manganese produced electrolytically is used mostly in the preparation of nonferrous alloys of copper aluminum magnesium and nickel and. Often ferromanganese usually about 80 manganese is the intermediate in modern processes.

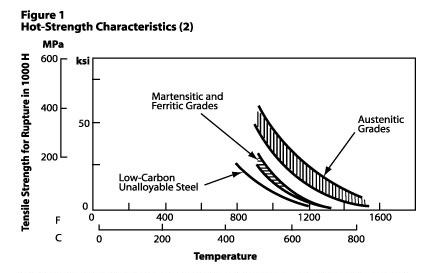

The chromium forms an oxide that inhibits rust in the alloy. The absorption of the blank sample containing no standard mn or kio 4 was measured to be 0 0395. The only things that they all have in common is that they are at least 50 1 iron fe they have at least 12 chromium cr and they. Austenitic manganese steels these steels are also known as hadfield steels and contain 10 to 15 of mn.

Manganese steel is used for very rugged service. Small amounts of manganese improve the workability of steel at high. Also manganese is likely to boost the rate of carbon penetration during the carburizing process. It generally contains 1 2 manganese.

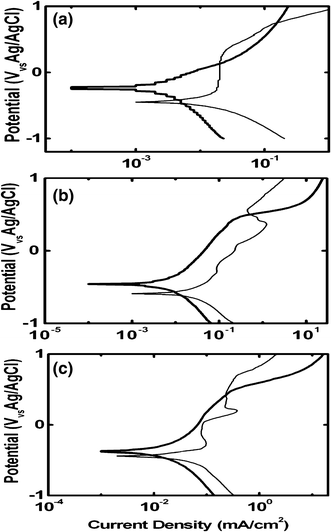

Many series of carburizing quenching and tempering structural alloy steels contain no more than 2 manganese. Containing 11 14 percent manganese it provides a hard wear resistant and self renewing surface over a tough unbreakable core. Chromium is added to steel to increase resistance to oxidation. Aisi 202 as a substitute for aisi 304.

There are literally dozens of stainless steel alloys. Steels often include 0 30 manganese but certain carbon steels can include up to 1 5 of manganese. Stainless steel contains more than 10 5 chromium along with nickel and manganese depending on the properties required. Stainless steels mn content in stainless steels can vary from 0 to 19.

Manganese is required for the hot rolling process of steel by combining it with sulfur and oxygen.