Refrigerant Pipe Insulation Thickness Ashrae

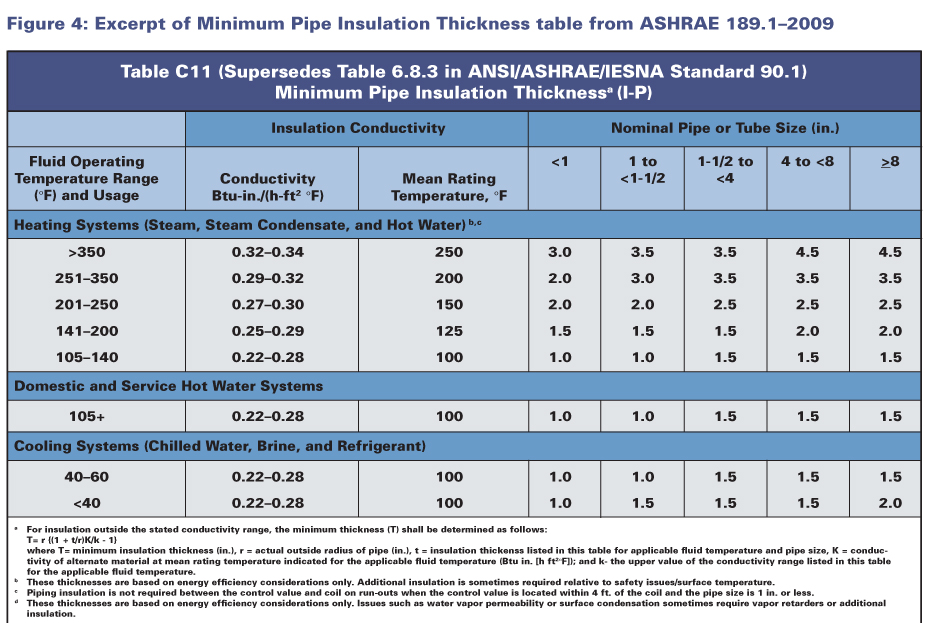

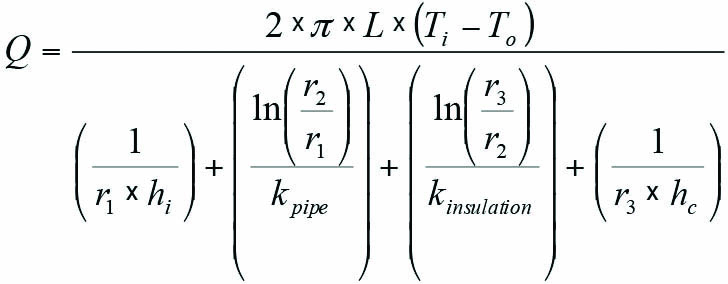

R actual outside radius of pipe in t insulation thickness listed in this table for applicable fluid temperature and pipe size.

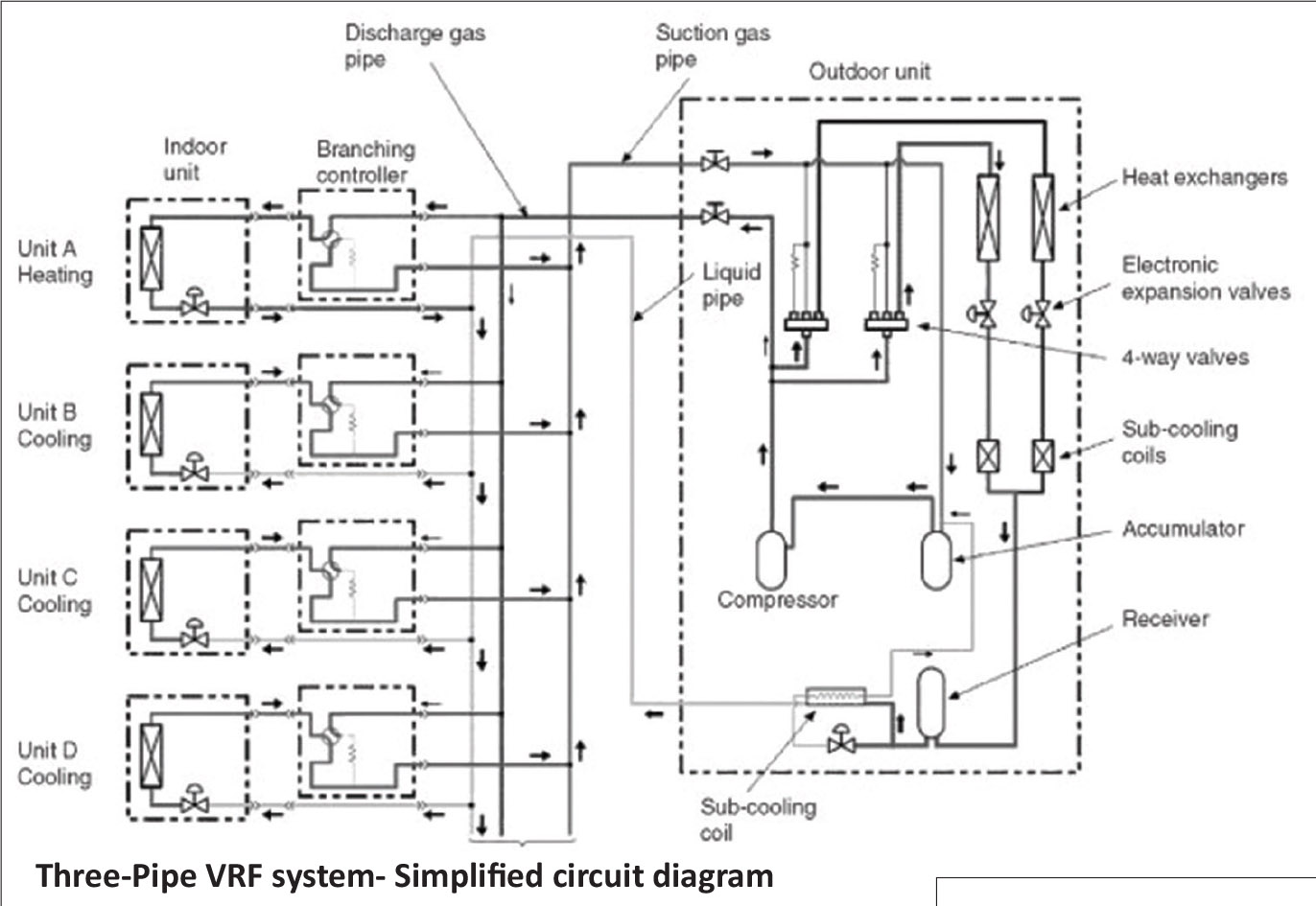

Refrigerant pipe insulation thickness ashrae. Insulation systems for refrigerant piping clicking on a company s name will take you to their web site. On steam distribution pipes in buildings those thicknesses will increase from 4 in. 46 manufacturer recommendations glue the joints glue the fittings vapor stop. Such as liquid refrigerant piping.

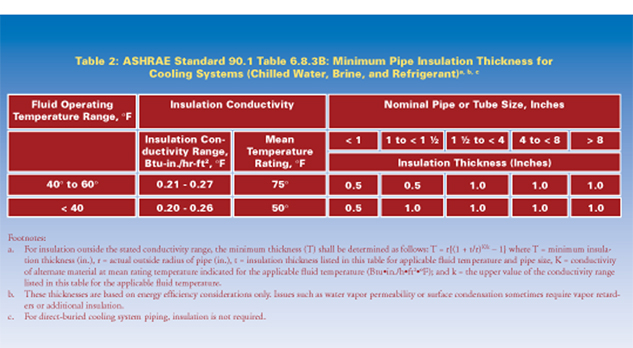

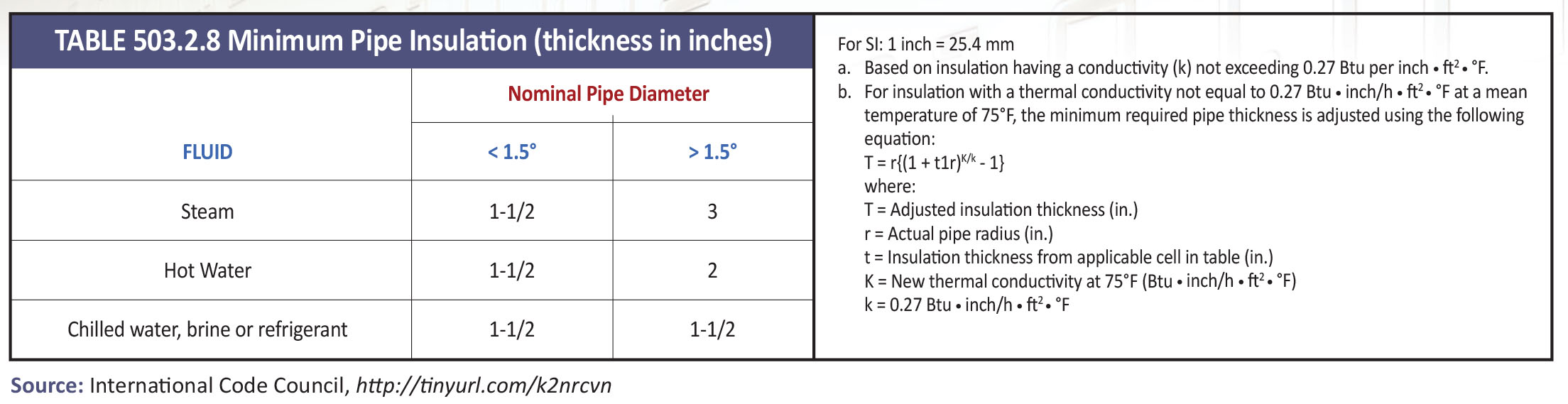

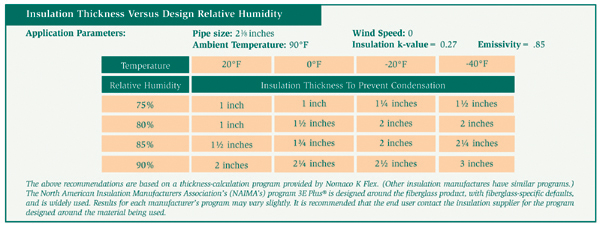

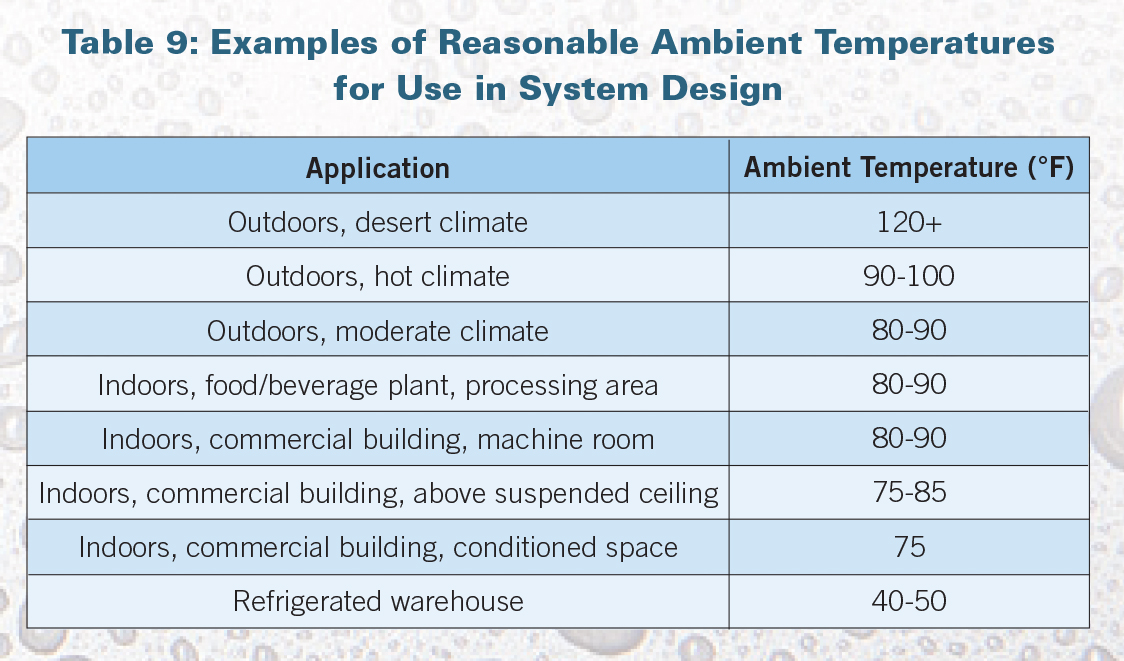

For pipes section 6 4 4 1 3 in ashrae 90 1 and section c403 2 10 in the iecc contain the identical table that shows the insulation thickness required depending on the pipe operating temperature and the size of the pipe these sections also give the thermal conductivity range at a specified mean temperature that the insulation must meet for the table to be applicable. Related commercial resources ashrae handbook refrigeration chapter. Guidelines for insulation selection thickness installation and maintenance are found in the 2006 ashrae handbook refrigeration in chapter 33 insulation systems for refrigeration piping reliability should be the primary concern when considering the design and installation for any application. Thickness to prevent heat gain and condensation.

Or less insulation is not required for. Pipe insulation requirements in commercial buildings continued ansi ashrae ies standard 90 1 2010 2012 iecc code notes 4 table c403 2 8 minimum pipe insulation thickness thickness in inches a fluid. We have replicated the 2016 building energy efficiency standards table 120 3 a pipe insulation thickness below for this review which matches table c403 11 3 of the iecc international energy conservation code and ashrae 90 1 table 6 8 3 1. On most pipe sizes when using materials such as mineral wool fiberglass and calcium silicate.

Use 1 1 2 thick wall on pipes larger than 2 ips. For domestic hot water systems use 1 thick fiberglass pipe insulation on pipes up to 2 ips. In piping 1 in. Chart shows minimum thickness to meet ashrae 90 1.

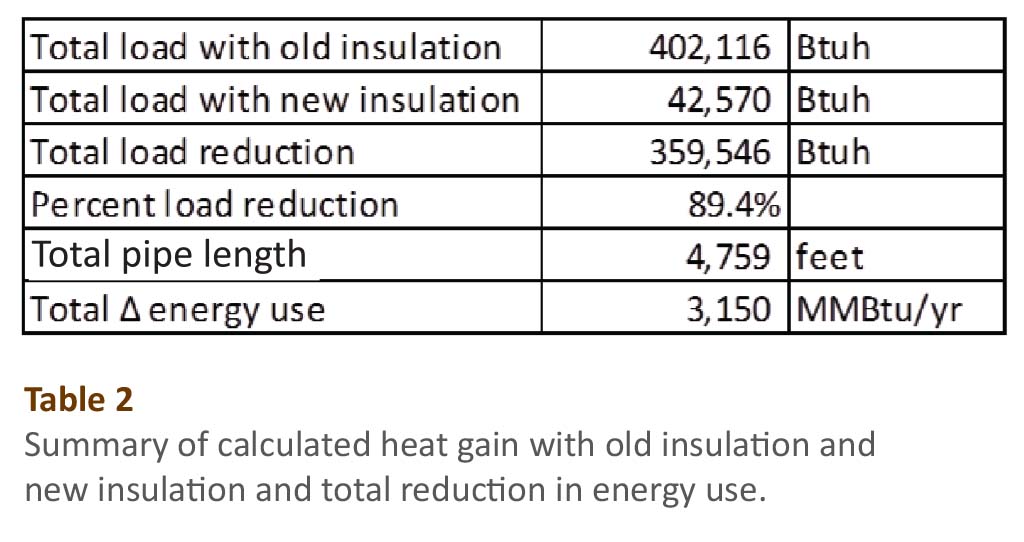

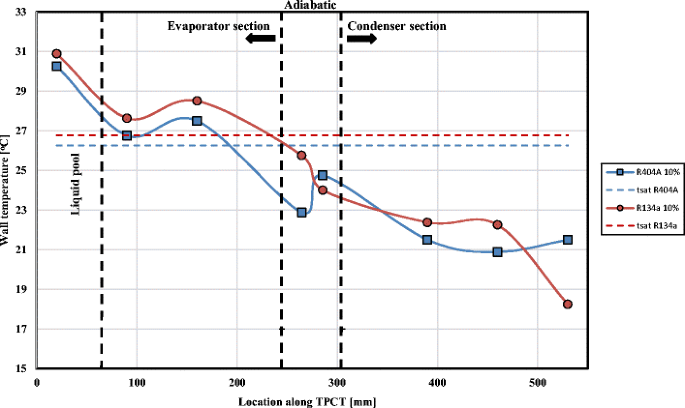

Proper mitered joints on piping insulation specification item mitered joints on refrigeration insulation improper insulation installation. Proper refrigeration system design attempts to minimize this change to less than 2 f 1 1 c per line. As refrigerant flows through pipes the pressure drops and changes the refrigerant saturation temperature. When ashrae standard 90 1 2010 takes effect later this year compliance will require greater pipe insulation thicknesses.

Minimum thicknesses to meet ashrae 90. Decreases in both pressure and saturation temperature adversely affect compressor performance.