Relief Cut Sheet Metal

If it is ok for the metal to rip the minimum bend relief is zero.

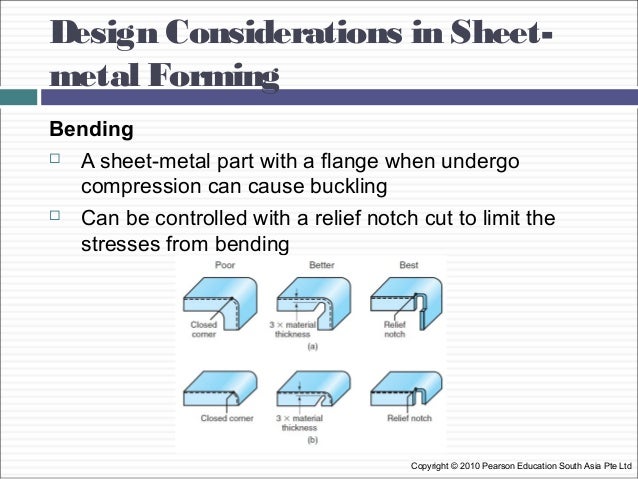

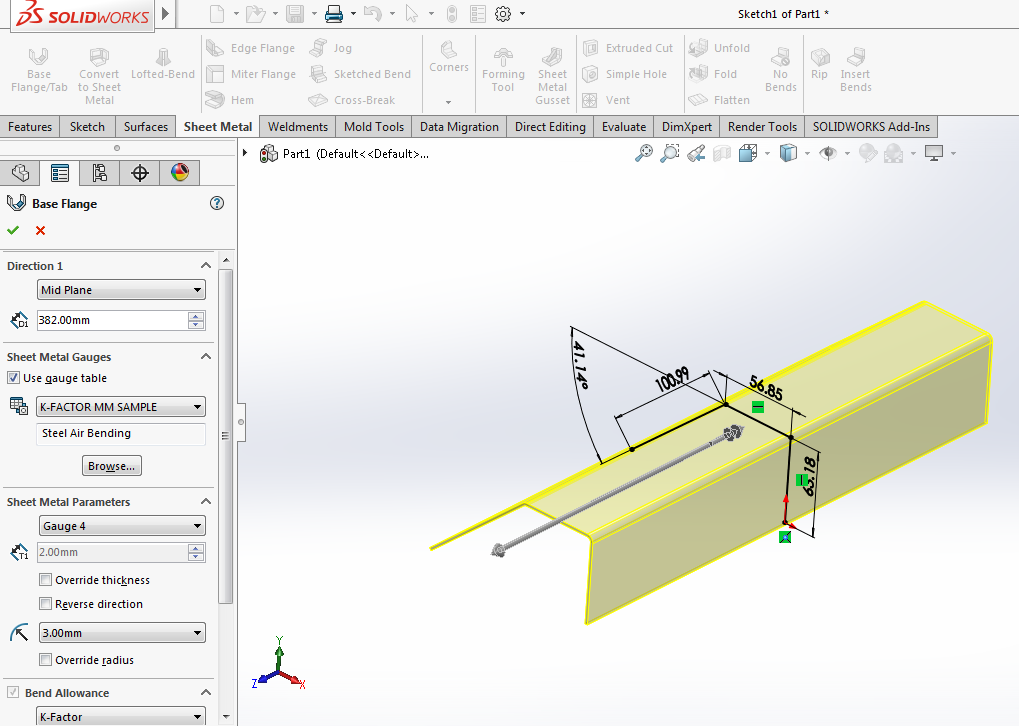

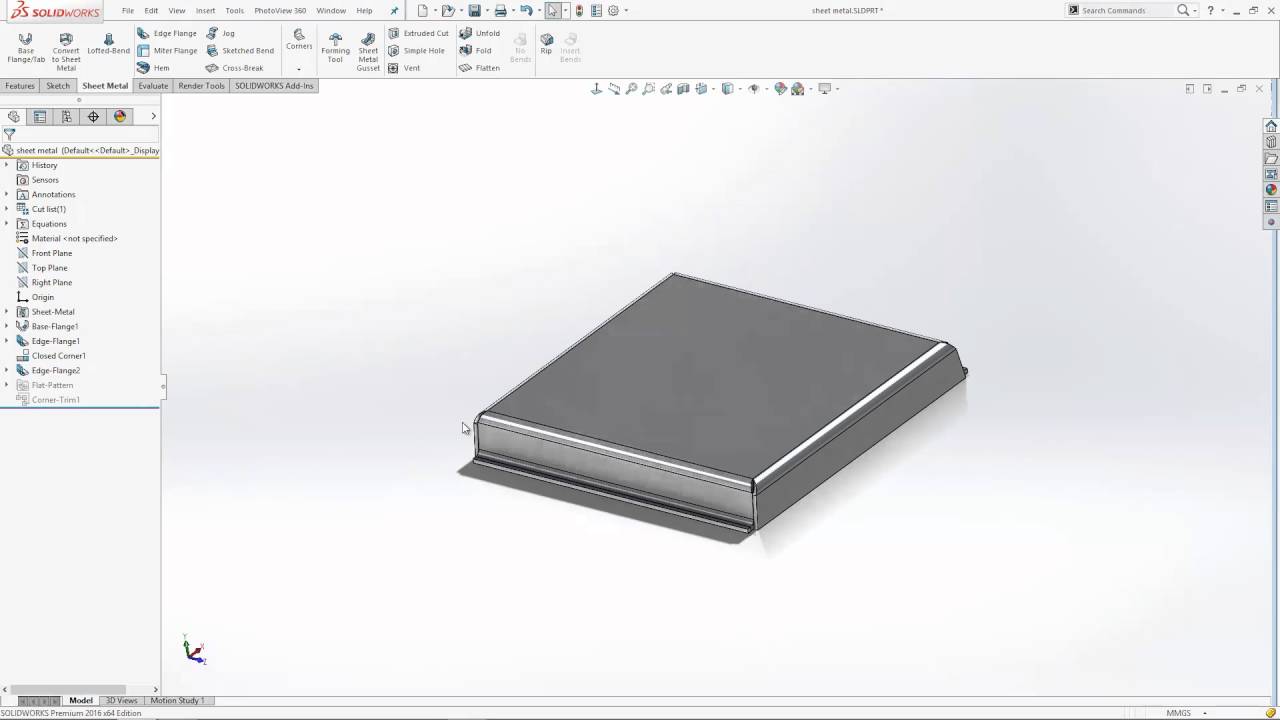

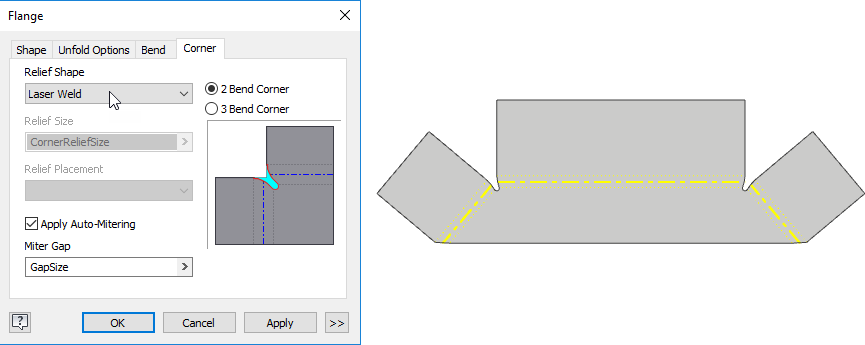

Relief cut sheet metal. Right click the sheet metal feature in the featuremanager design tree and select edit feature. In the propertymanager under auto relief change the type of relief cut. You can add a corner relief to a single sheet metal body. Bend 1 shows a a tear relief.

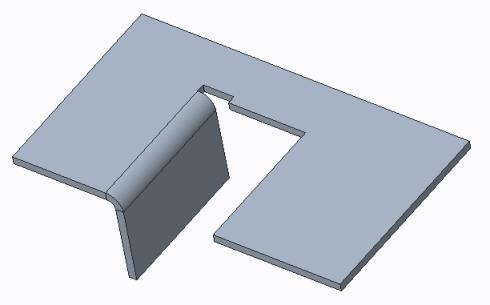

Bend 2 shows a rectangular relief cut into the part the depth of the relief should be greater than the radius of the bend. The width of the relief should be a material thickness or greater preferably a material thickness 1 64. Bend relief synchronous sheet metal is pretty cool even cooler than just normal synchronous modeling if you ll excuse that word. Relief cuts help parts avoid overhangs and tearing at bends.

For example if you make a partial flange as above using all the defaults the software makes relief cuts at the end of the bends as shown to the right. We would like to show you a description here but the site won t allow us. Bend relief and collars near pierced areas strengthen sheet metal parts. In general a minimum bend relief is equal to the material thickness plus the inside bend radius.

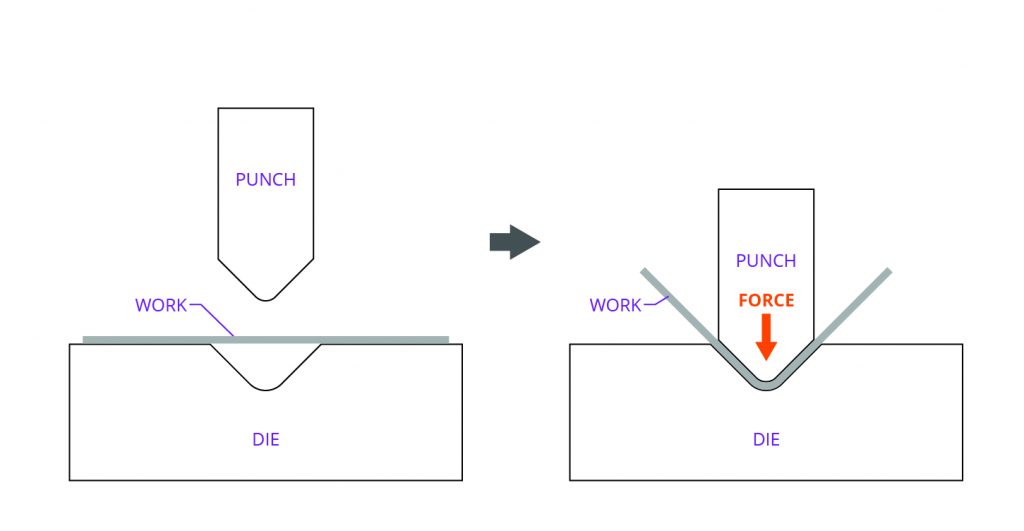

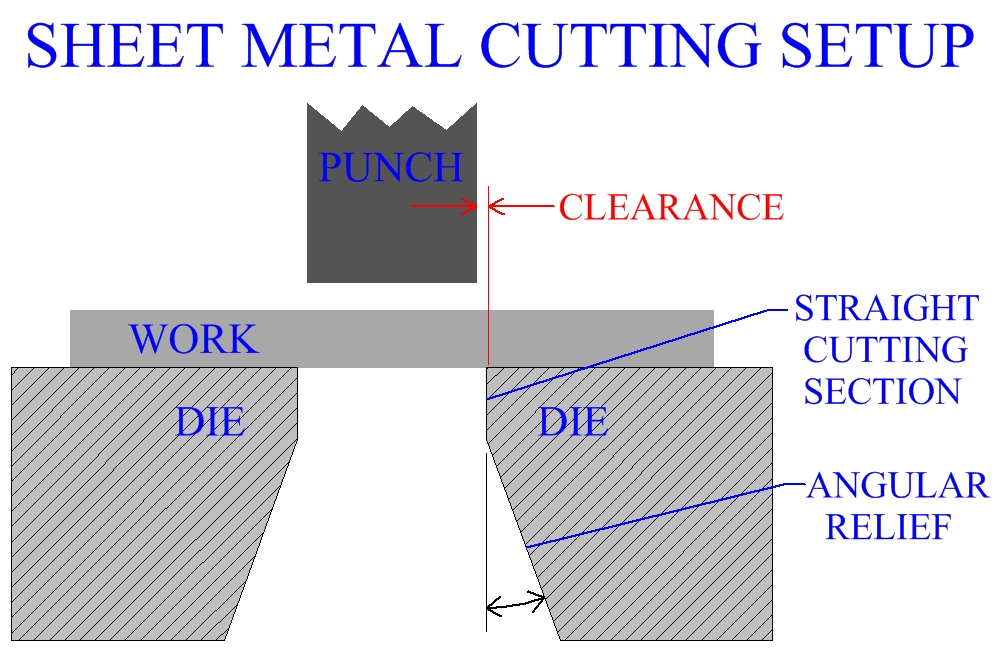

Sheet metal fabrication is the process of forming parts from a metal sheet by punching cutting stamping and bending. Sheet metal parts may have sharp corners but designing a fillet of the material s thickness will make parts more cost effective. To change the type of relief cut for all bends. In the corner relief propertymanager under scope select the sheet metal body to which to apply the corner relief.

The width of the relief should be the material thickness or greater. One benefit of a bend relief is that it makes the part easier to produce. Click corner relief sheet metal toolbar or insert sheet metal corner relief. Under corners click collect all corners to list all corners in the sheet metal body.

Grain structure in the metal sheet is critical for avoiding cracks in sheet metal parts with lugs or tabs that are cut on. To eliminate this a bend relief is added so the edge of the sheet metal is perpendicular to the bend.